To prevent showing casting stitches on the outside of the fabric French seams or flat felled seams are used to join sheer fabrics. I´ll show you a fastening for a skirt with a placket to be closed with hooks and eyes. Of course it can be used with heavier fabrics too.

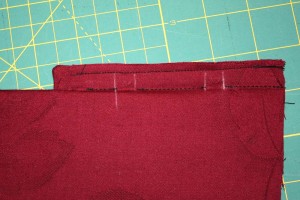

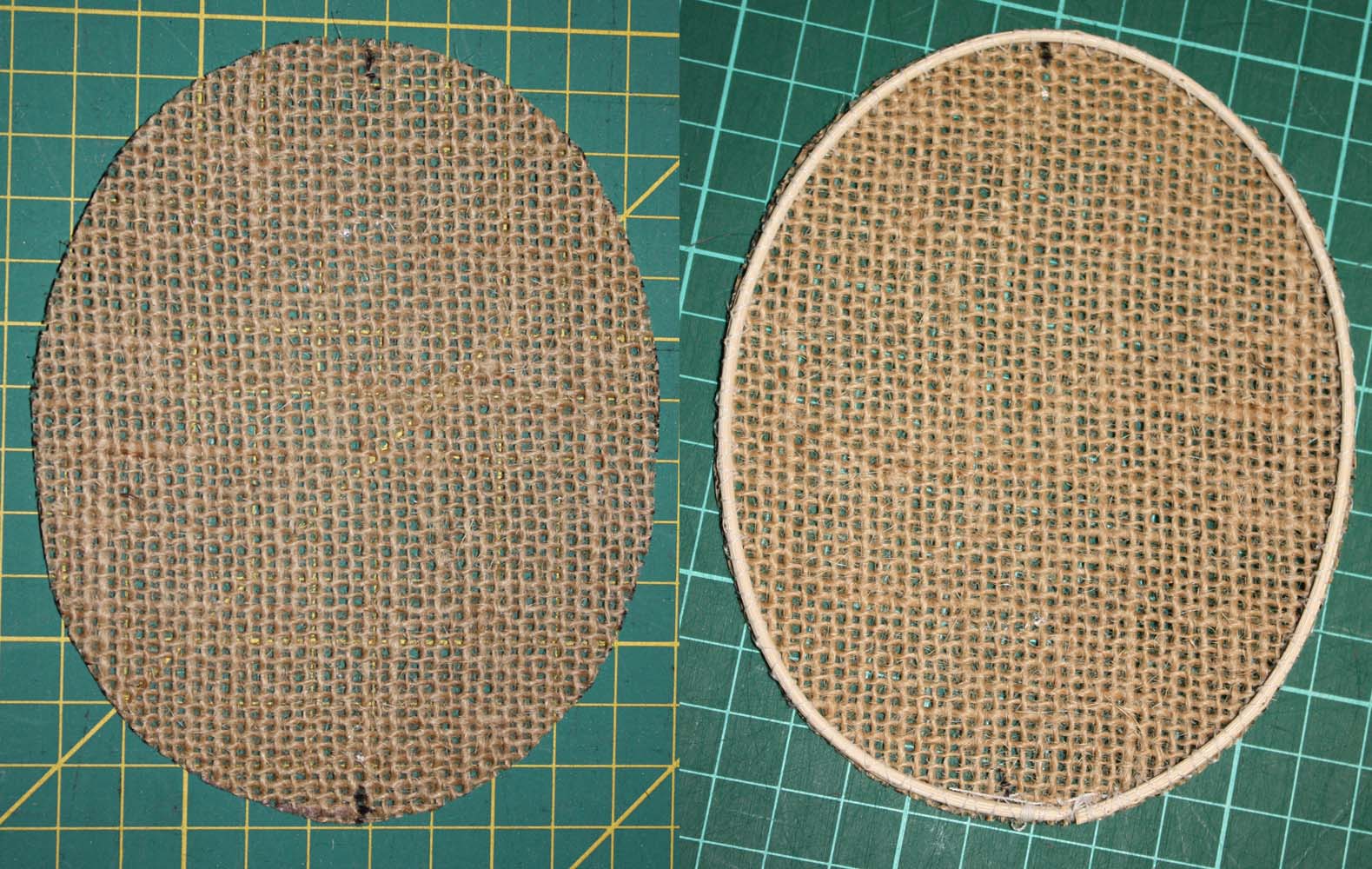

Fold the placket lengthwise right sides together. Sew along the bottom edge and along the long edge. Trim seam allowance, turn inside out and press. The width now should be the desired width of the placket e.g. 1 5/8” (4cm) + 5/8” (1,5cm). On the pic you see an overlock casted placket for comparison.

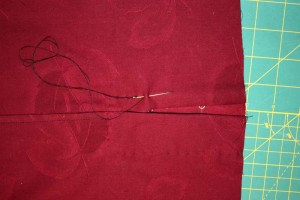

Mark seam allowance (5/8” (1,5cm)) at the right side of the placket and line up with the skirt edge, right sides together. Sew together close to the edge; stop about 5/8” (1,5cm) away from the bottom edge of the placket. Unfold the placket, mark position of eyes and sew them to the placket by hand so that they ride out just a little bit the sewing line.

Sew the facing to the other edge of the skirt. Line up with the edge, right sides together, fold up seam allowance of the bottom edge of the facing and sew.

Close skirt seam, line up edges exactly and pin together, fold away placket and facing, sew. The seam ends a little bit above the facing seam, take care not to catch the placket of facing while sewing.

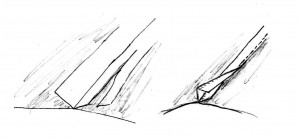

Press open seam allowance; clip on the placket side towards seam end. Trim seam allowance on the side of the facing to ¼” (0,5) cm. Fold seam allowance of the placket side over the trimmed seam allowance of the facing side to get a flat felled seam, sew.

Fold skirt at the placket aside and mark position of eyes. Sew along the seam line. Skip eyes, lock seam before and after. If you want a continuous seam use your hand wheel for not breaking the needle. Press edge carefully.

Fold in raw edge of facing. Sew facing, bottom edge and Seam allowance of placket through all layers with small pointed stitches.

Mark position of hooks and sew only to the facing. If wanted sew along the facing edge with pointed stitches for more stability.

Sew waistband as usual.